Are you ready to embark on a thrilling journey into the world of 3D printing? Imagine being able to create your own custom-made objects right from the comfort of your own home. With the rise of do-it-yourself 3D printers, this futuristic dream is now a reality. In this comprehensive guide, we will dive into the fascinating world of building your own 3D printer from scratch. Whether you’re a tech enthusiast or a curious hobbyist, get ready to unlock the secrets of this cutting-edge technology and unleash your creativity like never before.

Understanding the Basics of 3D Printing

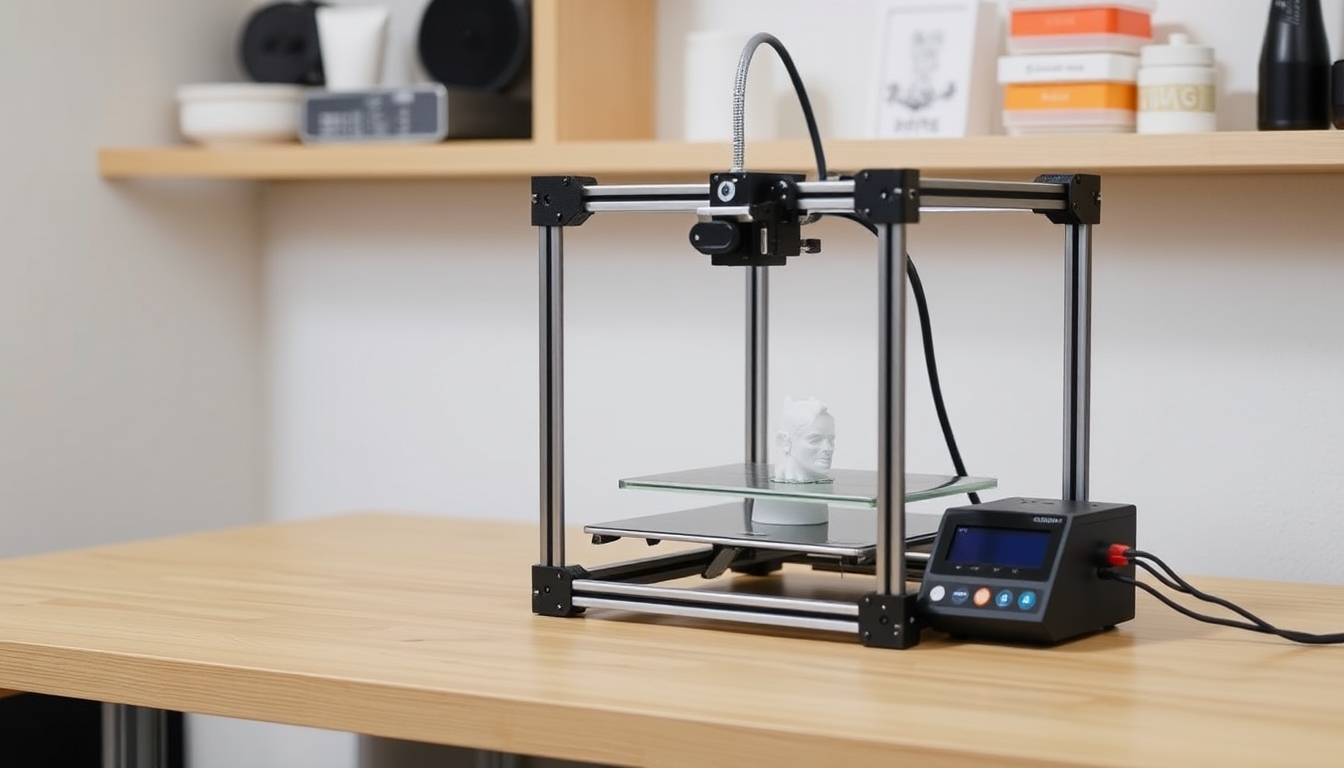

Before we delve into the exciting world of do-it-yourself 3D printers, it’s essential to grasp the fundamentals of this groundbreaking technology. 3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials based on a digital design.

At its core, a 3D printer is essentially a sophisticated machine capable of translating digital blueprints into physical objects. It does this by depositing successive layers of material, such as plastic or resin, until the desired object takes shape.

How Does a 3D Printer Work?

The process starts with creating or obtaining a 3D model, which can be designed using Computer-Aided Design (CAD) software or downloaded from various online repositories. The 3D model is then sliced into hundreds or thousands of thin layers using slicing software.

Once the slicing is complete, the 3D printer reads the sliced file and begins the printing process. The printer nozzle precisely deposits the chosen material layer by layer, following the instructions from the sliced file. This gradual building of layers eventually forms the final 3D printed object.

The Advantages of DIY 3D Printers

Building your own 3D printer offers a multitude of advantages. Firstly, it allows you to have full control over the entire process, from selecting the components to fine-tuning the printer’s settings. This level of customization enables you to tailor the printer to your specific needs and preferences.

Moreover, DIY 3D printers are often more affordable compared to pre-built models, making them an ideal choice for those on a budget. Additionally, as you assemble the printer yourself, you gain valuable knowledge and experience about the inner workings of this technology, empowering you to troubleshoot and maintain the printer with ease.

In the following sections, we will guide you through the step-by-step process of building your own 3D printer, providing you with the necessary resources and insights to embark on this exciting journey.

Gathering the Necessary Components

Building your own 3D printer requires careful planning and acquiring the right components. Here’s a breakdown of the essential parts:

1. Frame

The frame serves as the foundation of your 3D printer, providing stability and support. Common materials for the frame include aluminum, acrylic, or wood. Consider factors like durability, weight, and ease of assembly when selecting the frame material.

2. Motors and Electronics

Key components such as stepper motors, motor drivers, and control boards are responsible for precise movements and controlling the printer. Make sure to choose motors and electronics that are compatible with your chosen frame and meet the specifications required for your 3D printer build.

3. Extruder and Hotend

The extruder and hotend work together to feed and melt the filament, allowing it to be deposited layer by layer. Look for reliable extruders and hotends that can handle various filament types and provide consistent temperature control.

4. Power Supply

A stable and reliable power supply is crucial for the smooth operation of your 3D printer. Ensure that the power supply can deliver sufficient voltage and current to support the printer’s components.

5. Bed and Build Plate

The bed and build plate provide a stable surface for your prints. Consider factors like size, leveling mechanisms, and heating capabilities when choosing an appropriate bed and build plate for your specific needs.

6. Filament and Filament Sensor

Select high-quality filaments compatible with your printer’s hotend. Additionally, a filament sensor can detect filament breakage or running out, pausing the print and preventing potential failures.

By carefully selecting and sourcing these components, you’ll lay a solid foundation for your DIY 3D printer. In the next section, we’ll dive into the assembly process, guiding you step-by-step towards bringing your printer to life.

Assembling Your DIY 3D Printer

Now that you have gathered all the necessary components, it’s time to put them together and bring your DIY 3D printer to life. Follow these step-by-step instructions:

1. Frame Assembly

Start by assembling the frame according to the manufacturer’s instructions. Follow each step carefully, ensuring that all the components are securely fastened. Double-check the alignment and squareness of the frame to guarantee stability.

2. Mounting the Motors and Electronics

Attach the stepper motors to their designated positions on the frame. Connect the motor drivers and control board according to the wiring diagram provided by the manufacturer. Take your time to ensure proper alignment and secure connections.

3. Installing the Extruder and Hotend

Mount the extruder assembly onto the designated location on the frame. Attach the hotend to the extruder assembly, making sure it is properly secured. Connect the necessary cables and ensure smooth movement of the extruder assembly.

4. Power Supply Connection

Connect the power supply to the control board, following the manufacturer’s instructions. Take necessary precautions to ensure safety, such as proper insulation and grounding.

5. Bed and Build Plate Installation

Install the bed and build plate onto the frame. Make sure it is level and properly aligned. If your printer includes a heated bed, connect the necessary cables and ensure proper temperature control.

6. Filament Sensor Integration

If your printer includes a filament sensor, mount it onto the frame and connect it to the control board. Ensure that it is properly calibrated and functioning correctly.

By following these assembly steps diligently, you’ll soon have your very own DIY 3D printer ready to bring your creations to life. In the next section, we’ll explore the essential software and settings required to operate your printer successfully.

Software and Settings for Operating Your DIY 3D Printer

Now that your DIY 3D printer is assembled, it’s time to set up the necessary software and configurations to ensure smooth operation. Here are the key steps:

1. Firmware Installation

Install the appropriate firmware for your printer’s control board. Popular firmware options include Marlin, Repetier, and Smoothieware. Follow the firmware’s documentation or guides provided by the manufacturer to flash the firmware onto the control board.

2. Slicing Software Setup

Select a reliable slicing software to prepare your 3D models for printing. Some popular options include Ultimaker Cura, PrusaSlicer, and Simplify3D. Configure the slicing software by inputting your printer’s specifications, such as build volume, filament diameter, and nozzle size.

3. Calibration and Bed Leveling

Calibrate your printer’s settings, including steps per millimeter for each axis, extruder steps, and PID tuning for temperature control. Additionally, perform bed leveling to ensure that the print surface is even and properly aligned with the nozzle.

4. Filament Loading and Settings

Load your chosen filament into the extruder and adjust the filament settings in your slicing software accordingly. This includes temperature settings, retraction distance, and print speeds. Experiment with different settings to optimize print quality.

5. Test Prints and Troubleshooting

Before diving into complex prints, start with simple test prints to ensure that your printer is functioning correctly. Monitor the print process closely, checking for any issues such as under extrusion, layer shifting, or adhesion problems. Troubleshoot as needed by adjusting settings or examining mechanical components.

6. Maintenance and Upgrades

Regularly maintain your DIY 3D printer by cleaning the nozzle, lubricating moving parts, and checking for loose connections. Stay informed about firmware updates and consider upgrading components or adding new features to enhance your printer’s capabilities.

By following these software setup and configuration steps, you’ll be well-equipped to operate your DIY 3D printer effectively. In the next section, we’ll explore some exciting projects and possibilities that you can explore with your newly built printer.

Exploring the Possibilities: Projects and Applications for Your DIY 3D Printer

Now that you have your DIY 3D printer up and running, it’s time to unleash your creativity and explore the wide range of projects and applications that this technology offers. Here are a few exciting possibilities:

1. Prototyping and Product Development

Use your DIY 3D printer to create prototypes of your product ideas. This allows you to test and refine designs before investing in expensive manufacturing processes.

2. Customized Accessories and Decorations

Create unique accessories and decorations tailored to your personal style. From custom phone cases to personalized jewelry, the possibilities for customization are endless.

3. Educational Tools and Models

Print educational tools and models to enhance learning experiences. Create anatomical models, historical landmarks, or scientific demonstrations to aid in education and understanding.

4. Home Repairs and Upgrades

Fix broken household items or upgrade existing ones using 3D printed parts. From replacement knobs to customized brackets, your DIY 3D printer can save you time and money on home repairs.

5. Artistic Creations

Let your artistic side flourish by using your DIY 3D printer to create sculptures, intricate patterns, or even functional art pieces. Experiment with different materials and techniques to push the boundaries of artistic expression.

6. Community and Open-Source Projects

Join the thriving community of 3D printing enthusiasts by contributing to open-source projects. Share your designs, collaborate with others, and explore the innovative applications of this technology together.

These are just a few examples of what you can achieve with your DIY 3D printer. The only limit is your imagination. So, go ahead and start exploring, creating, and sharing your amazing 3D printed creations with the world.

Tips for Success with Your DIY 3D Printer

To ensure a smooth and successful 3D printing experience with your DIY printer, consider the following tips:

1. Patience and Calibration

Take the time to properly calibrate your printer and fine-tune its settings. Patience is key when it comes to achieving high-quality prints.

2. Start with Simple Prints

Begin with simple prints to familiarize yourself with the printer’s capabilities. Gradually increase complexity as you gain confidence and experience.

3. Experiment with Different Filaments

Explore a variety of filaments such as PLA, ABS, PETG, and more. Each filament type has its own characteristics, so experiment to find the one that suits your needs best.

4. Learn from the Community

Tap into the knowledge and experiences of the 3D printing community. Join online forums, participate in discussions, and seek advice from experienced enthusiasts.

5. Regular Maintenance

Keep your DIY printer in optimal condition by performing regular maintenance. Clean the nozzle, lubricate moving parts, and replace worn-out components when necessary.

6. Stay Updated with Technology

Stay abreast of the latest advancements in 3D printing technology. This ensures that you are aware of new features, upgrades, and software improvements that can enhance your printing experience.

7. Embrace the Learning Journey

Remember that 3D printing is a continuous learning process. Embrace the journey, learn from failures, and celebrate successes as you explore the endless possibilities of this exciting technology.

By following these tips, you’ll be well on your way to becoming a proficient DIY 3D printer enthusiast. Enjoy the process, and let your creativity soar!

Conclusion: Embrace the DIY 3D Printing Revolution

Building and owning a DIY 3D printer opens up a world of possibilities for creativity, innovation, and problem-solving. With the right components, software, and a dash of curiosity, you can embark on a thrilling journey into the realm of additive manufacturing.

From prototyping and customization to educational tools and artistic creations, your DIY 3D printer empowers you to bring your ideas to life. With each successful print, you’ll gain confidence and unlock new opportunities for exploration.

Remember, the key to success lies in patience, calibration, and continuous learning. Embrace the challenges and celebrate the breakthroughs as you join the vibrant community of 3D printing enthusiasts.

So, what are you waiting for? Start gathering your components, dive into the assembly process, and embark on your own DIY 3D printing adventure. Unleash your creativity, push the boundaries of what’s possible, and embrace the revolution of additive manufacturing.

Happy printing!

In conclusion, building your own DIY 3D printer is an exciting and rewarding endeavor. By understanding the basics of 3D printing, gathering the necessary components, and following the assembly and setup process, you can unlock endless possibilities for creativity and innovation. Whether you’re a hobbyist, an entrepreneur, or an educator, a DIY 3D printer allows you to bring your ideas to life and explore the fascinating world of additive manufacturing.

Throughout this guide, we’ve covered the important steps and considerations for building and operating your DIY 3D printer. From selecting the right components to calibrating the printer and exploring different filaments, each piece of the puzzle contributes to your success. Remember to stay connected with the 3D printing community and embrace the learning journey as you experiment with new projects and applications.

So, why wait? Start your DIY 3D printing adventure today and immerse yourself in the remarkable world of this cutting-edge technology. Unleash your creativity, solve problems, and make your ideas a reality with your very own homemade 3D printer. The possibilities are limitless, and the future of additive manufacturing is in your hands!